If you think you are tired of your everyday industrial work, let automation take over your job. So having said that, in today’s article, get ready to witness the most amazing smart factory automation, industrial manufacturing automation, automation trend in the supply chain, and high tech production with intelligent robots taking over most of the tests.

Companies will make an urgent effort to achieve carbon neutrality

Manufacturing industry trends are in the spotlight as the growing industry undergoes its most significant automation transformation in recent years. Automation firms are rehiring more workers every day due to the latest technology in the manufacturing and services industry. Furthermore, the industrial manufacturing industry is undergoing an industrial revolution known as Industry 5.0.

Hey, how’s it going, everyone? This is James, and welcome to Make An App Like. And if you’re new here, let me tell you we are a technology updated site and post interesting content like this. And so, without further ado, let me take you to my number one. Number one is industrial automation.

latest trends in industrial automation of 2024

1. Industrial Internet of Things

The Industrial Internet of Things (IIoT) is a term that refers to the interconnection of equipment in all industries. Sensors and interconnects have advanced to the point where things may communicate with users without them having to be there. In addition, devices can use the internet and GPS connectivity to guide their actions. The agricultural business, for example, relies on GPS to direct their tractors and embedded sensors to tell farmers of anything from fuel to crop numbers remotely; therefore, the IIoT has become critical. Sensors in wind turbines and data-gathering drones are two other agricultural applications.

2. Demand for Voice-activated Automation

In the Industry 4.0 work environment, voice-activated automation allows for more flexibility and better product flow. You can say voice automation is the new trend in industrial automation. Voice assistants such as Alexa, Siri, and Google Play are becoming increasingly popular in homes. By incorporating voice-activated automation into the workplace, businesses can assign different tasks to employees. Employees can utilize their voices to direct important activities because some employees speak faster than they type. Voice-activated automation may appear complicated at first, but it will open up many doors in the future years.

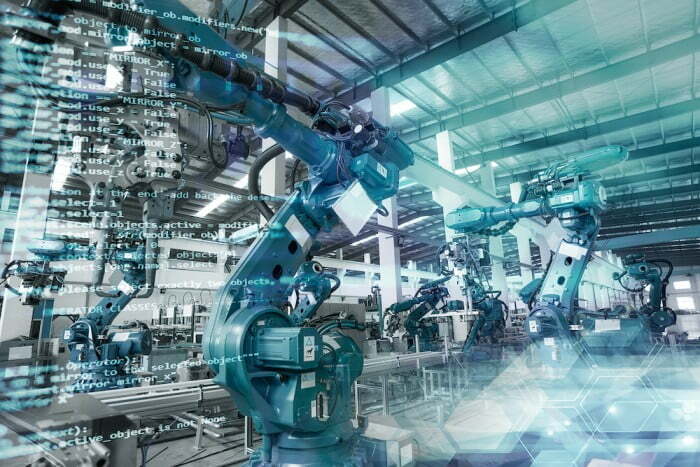

3. Industrial Automation & Robotics Process

Hyperconnectivity is one of the major characteristics representing the Fourth Industrial Revolution era. The cutting-edge technologies which are closely connected like a spider web is another characteristic of the era of hyperconnectivity. Industrial Automation refers to the automated manufacturing system, including designing and producing stages through robots and computers.

Along with the continuing growth of the technology market, industrial automation has brought about changes to different industrial areas, aside from the manufacturing sector. The distribution industry is one of the examples.

The automated system has increased the working efficiency and has contributed to reducing errors that might occur during the working process; an industrial robot is one of the necessary elements for industrial automation.

Three-dimensional recognition of the environment has become possible along with the implementation of various sensors, and they have played a significant role in the automation of industries.

A collaborative robot is one of the industrial robots that has garnered much attention. It can work rapidly, increase productivity and realize coexistence with humans.

4. Building intelligent factories in the cloud technology

Factory environments are advancing cloud computing and smart sensors in addition to virtual reality and robotics. These sensors can transform data into multiple units of measurement, communicate with other machines, record statistics, and feedback, and turn things off.

IoT capabilities can measure and assess production quotas, consolidate control rooms, and construct predictive maintenance models. The Internet of Things enables people to acquire the correct information at the right moment to make the best decisions. For example, a speedometer can display how fast you’re driving compared to how fast you were driving yesterday.

Additionally, what establishes best practice has changed as well? You can learn more about the industrial automation services of Sirinsoftware.com.

5. The Smart Factory

The smart factory of China’s home appliance maker glance is fully automated. It has four smart production lines, and each of them is equipped with 17 mechanical arms.

The robotic arms are in manufacturing, including material input, processing, and assembly. On average, a product rolls off the assembly line every 6.7 seconds. The factory has an annual production capacity of 11 million home appliances.

6. Cloud innovation Energy Efficienteeds up

Cloud innovation is the same old thing any longer. However, as the innovation proceeds to develop and turns out to be progressively simple to set up and utilize, its reception rates continue climbing – worldwide spending on cloud administrations generated from US$145 billion (2017) to $332 billion (2021) and is relied upon to reach $397 billion out of 2022 (Statista).

For makers and associations hoping to further develop their stock administration processes, cloud innovation addresses a significant open door – particularly remote working.

7. Predictive Maintenance

Predictive maintenance is a term used in the manufacturing industry to describe sensor data and artificial intelligence (AI) to detect failure patterns in machinery and components. This is the next latest trend in industrial automation. Manufacturers can take preventative measures and maintain their equipment more successfully if they know when a machine or part is likely to fail.

This isn’t only true for expensive new equipment. Siemens has installed such sensors on older motors and gearboxes, and claims to evaluate a machine’s state, detect abnormalities, and repair equipment before they fail by evaluating the data from these sensors. This demonstrates how predictive maintenance techniques can be used on older machines.

8. Edge computing platforms become edge automation platforms

Edge computing platforms and apps are fast growing in popularity, yet they frequently necessitate the installation, programming, operation, and support of corporate IT staff with particular capabilities.

As a result, edge automation systems have been developed to give the full capabilities and benefits of computing at the edge, such as gathering, analyzing, processing, and storing data locally in real-time at or near the collection site.

The main distinction is that people who do not have specific IT expertise will support these new edge automation platforms.

The edge automation platform is also built to run indefinitely without professional onsite or remote IT support. In 2022, new edge automation platforms are expected to be introduced.

9. Web of Things a ‘return to development’ gas pedal

Like a cloud, the Internet of Things (IoT) has been around for some time now, and interest in this innovation has become consistent throughout the long term. In any case, 2020 denoted a lull for IoT reception rates because of the COVID-19 pandemic, as per the International Data Corporation. Numerous organizations couldn’t bear to zero in on advancement over strength.

In any case, as the world continues and we send off into 2022, the IDC anticipates that interest in IoT should not just increment once more (from 8.2% YOY in 2020 up to a CAGR of 11.3% for the 2020-2024 period), yet to likewise assist organizations with continuing from the pandemic.

10. 5G Boosts Interconnectivity

Small and medium enterprises will be able to take advantage of new prospects in their industry and better satisfy the demands of their customer’s thanks to 5G’s improved speed and reliable mobility.

Small and medium business owners that are computer aware are researching the benefits of 5G technology, how they may be used to revolutionize their operations, and what they should do to prepare.

5G has the potential to greatly increase the UK economy by allowing new and existing technologies such as the Internet of Things (IoT), big data, driverless vehicles, smart cities, and augmented and virtual reality to achieve new levels of potential.

The speed at which data is transmitted throughout the network will be greatly improved by 5G, permitting a massive expansion in the use of internet-connected products.

11. Energy Efficient

Manufacturing businesses increasingly recognize that energy efficiency is a critical component of lowering expenses and increasing profit margins. Factories aim to incorporate onsite renewable energy sources to lessen their reliance on the electrical grid. In addition to being ecologically conscious, utilizing the most available renewable energy source at a given geographic area will increasingly make economic sense. Tesla’s so-called Gigafactory, which is now under construction in Nevada and will have a final footprint of 1.9 million square feet, is estimated to generate more renewable energy than it will consume due to its geothermal, solar, and wind energy.

12. Energy Efficiency Motors in Factories

The adoption of high-efficiency motors will be another huge potential for factories. Factories utilize up to 40% of all electrical energy produced worldwide, with motors alone accounting for about 30%. The supply side of the energy equation is being addressed by renewable energy sources and battery technologies, while efficient motors are addressing the demand side. To reduce the cost and downtime associated with future upgrades, machines must be designed to allow easy motor retrofits.

13. Intelligent business process automation

The transition to Industry 5.0 solutions – which include connectivity, advanced analytics, intelligent business process automation, and advanced manufacturing technologies – began before the COVID-19 pandemic and accelerated during it, with companies looking to build resilience and radically improve operations, production efficiency, speed to market, customer service, and end-to-end supply chain transparency.

14. Cybersecurity Automation in industrial automation

In the last two years, the pandemic has resulted in a massive increase in the usage of smart gadgets and a data explosion. This has also opened up many opportunities for unscrupulous hackers to seek out victims and demand ransomware in exchange for private information. Cyber automation is becoming increasingly important to respond to every alert or threat posed by cyberattacks. Security Orchestration Automation and Response can help alleviate the strain of cybersecurity by evaluating which actions require human engagement and which can be completed completely autonomously. Cybersecurity technology is getting increasingly automated.

Here are the top automation trends in manufacturing of 2024

- Seeing around corners in 360° in manufacturing industry

- Roles will shift as automation and robotics becomes more prominent

- Viewing the fourth wave in 3D in manufacturing industry

- Supply chain disruptions will require workarounds and effective internal communication

- Advanced manufacturing on autopilot in industrial automation

- Building intelligent factories in the cloud technology

- Robots on the rise i.e. managed by humans

Top 7 Manufacturing Trends for 2022

- Increased Output Amidst a Decline in Labor Force

- Artificial Intelligence

- Companies will have to focus on employee retention

- Cybersecurity Automation

- Continued Efforts to Solve and Manage Supply Chain Issues

- Industry Will Bridg The Skills Gap With Tech

- Building a Resilient Workforce

- Asset Management By OEMs

- Automation and Robotics are Redefining

- 5G Boosts Interconnectivity

- More Focus on Carbon Neutrality

- Manufacturing Worker Roles

- Increased importance of HR in Attracting and Retaining Manufacturing Workers

- Employees Participating in Continuous Learning and Improving Skills

Conclusion of industrial automation market trends

Much has been said about how the fourth industrial revolution will allow manufacturers to use improved tools at all stages of the manufacturing process. While the fourth industrial revolution undoubtedly improved operational efficiency, it is time to focus on industry 5.0, a precursor to the sixth revolution.

One of the fastest-growing production areas in Latin America is process and manufacturing automation. Latin America has evolved into a block of growing economies fuelled by manufacturing, with a CAGR of slightly more than 11% predicted between 2025 and 2025.

According to a survey by Robotic and Automation News, the top market drivers are efficient inventory management and warehousing. Nonetheless, a wide range of factors is expected to impact manufacturing lines in the coming decade.

Automation is impacted by the convergence of information and operations technology, which is increasingly progressing as an important aspect of factory automation. Since its production process does not risk being distracted, IO/OT fusion supports humans in automated manufacturing.

Top 20 ICO App & Software Development Companies in USA, UK 2024

Top 20 ICO App & Software Development Companies in USA, UK 2024